When COVID cases in the U.S. were counted in four digits but rising fast, we at Crash Space looked for ways we could help. Already by that point, there were shortages of everything: Personal protective equipment (PPE), groceries, information. We found designs online for emergency ventilators, face masks, face shields, etc. that could be made with 3D printers, laser cutters and other prosumer tools we use. In the flurry for ideas and testing, I may have built a cardboard-iron lung.

One member who is connected with a local hospital relayed that they didn’t have enough protective gear to go around, and what they had was to be reserved for procedures. But a virus doesn’t wait for a procedure to spread. We decided that would become the focal point to maximize our impact.

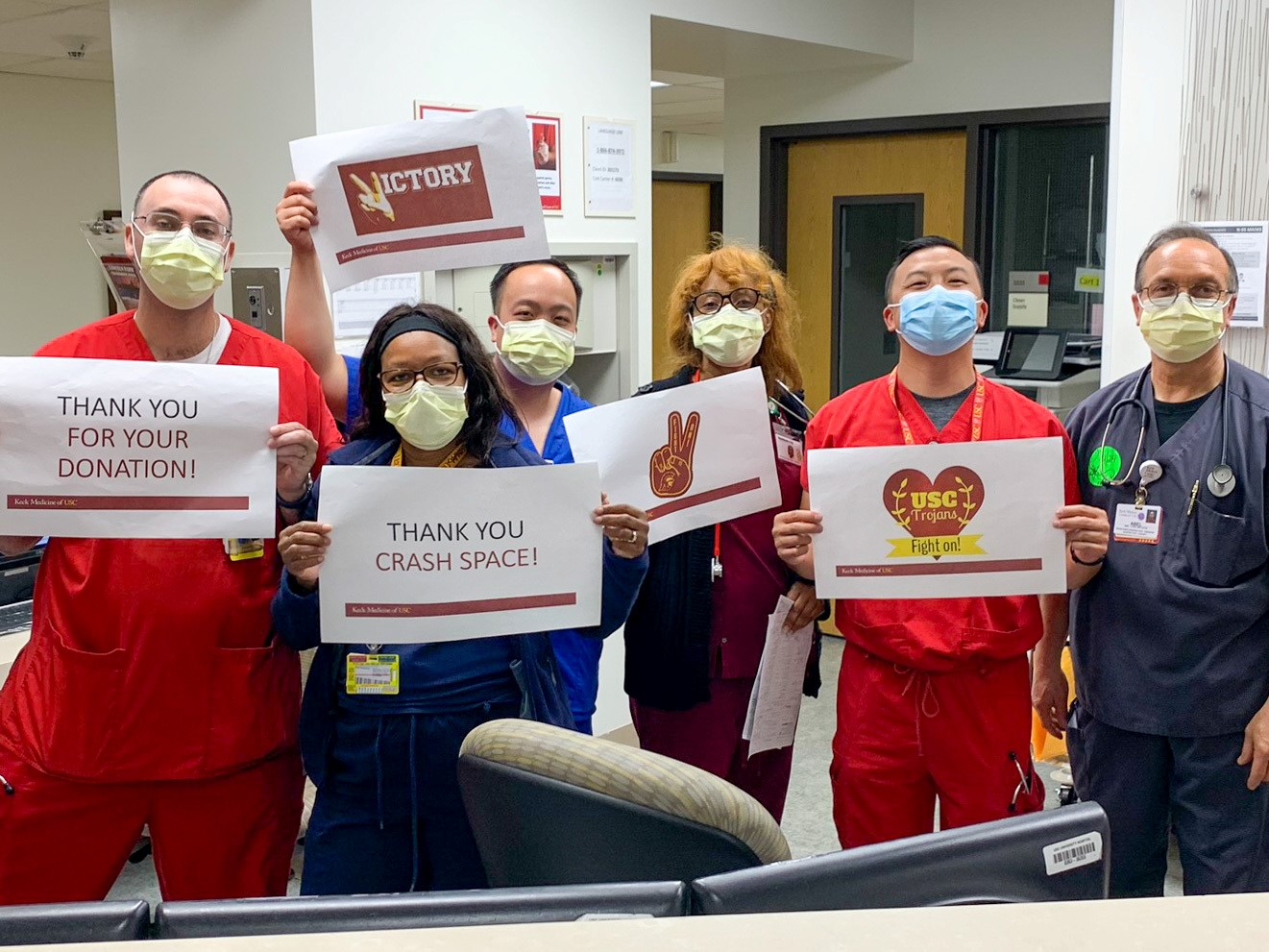

We partnered with two of the premier teaching hospitals in L.A., and presented some of what we could produce. This would turn out to be a crucial step. It was through these partnerships that sanitization methods were established, and the designs were revised to make up for shortcomings and make improvements. I can imagine what would go through a doctor’s head if we just handed them a box of plastic face masks. Were they sterile? How are parts changed? Do they work?

We all wore multiple hats, but officially, I took logistics. I built out our contactless dropoff areas, safe handling, inventorying and delivery procedures. As word spread among others in the L.A. area wanting a way to help, I wrote our core construction communications to be concise but thorough. People were justifiably panicked, and I wanted every word, <H2> tag and bold to convey its meaning exactly, and nothing more.

We outgrew our main building, and shifted operations to the hall of Covenant Presbyterian. We expanded assembly and delivery, and in talking with our hospital partners, we created new products for new problems. E.G. If you need to wear one face mask all day, comfort is safety.

I’ve read about other hospitals sending boxes of well meaning maker produced PPE straight to the trash. Maybe the items would have been acceptable after a STERRAD cycle, or a spraydown with 70% isopropyl alcohol. But maybe the designs would have allowed aerosols through crevices. Maybe a foam spacer would cover those crevices. But maybe that foam would be porous and harbor the virus. I don’t know. Collaborate with the people using your product(s).

Share: